World top-tier PVD metallic color coating technology | DSP

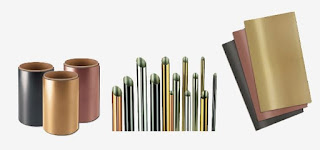

The DSP Co., Ltd. is a worldwide top-tier color coated metal sheet and tube manufacturer to produce exterior walls, exterior roofs, internal walls, interior ceilings, interior flooring, Elevator cabins, Elevator doors, Elevator jambs, Canopies, Columns. Also it provides the colored metal sheet and tube used in the production of vehicles and home appliances.

DSP delivers such beauty of metallic color to the world as a global leading company in PVD metallic color coating technology.

DSP’s PVD color coating technology

Physical vapor

deposition or PVD is a process of producing a metal vapor that can be deposited

on conductive materials as a thin, highly pure metal or alloy coating. The

process is performed in a vacuum chamber at a high-degree vacuum state using a

cathode arc source. Single or multiple layer coatings may be applied during the

same process cycle. stainless steel building

What advantages of DSP’s PVD color coating technology

ü

Large resistance to rust and scratches (Surface

hardness is 10 times stronger than normal stainless steel.)

ü

Various colors available, luxury and elegant colors are available

ü

Excellent durability of coatings and colors

(semi-permanent)

ü

Eco-friendly process

ü

Saving maintenance and replacement cost

What DSP’s PVD color coating machine

ü

Titanium coated vacuum chamber

ü

Titanium coated vacuum roll to roll machine

What process DSP’s PVD color coating work

ü

Stainless steel plates are processed in sealed

containers that can hold hundreds of parts at a time.

ü

The air is pumped out of the container, creating a

vacuum atmosphere equal to one billionth of air pressure, and blocking the

pressure present in the space.

ü

In the case of argon gas, it enters the container

and then becomes converted into particles smaller than an atom. These particles

are sprayed onto the surface for heating. interior stainless steel

manufacturer

ü

Particle spraying and the heat generated completely

clean the surface of the plate.

ü

The injected particles adhere to titanium and have

extremely resistant metallic properties, which evaporate the produced titanium

metal and atoms and are deposited on the surface of the object to form TiN, TiC,

and TiNC films. Because of their high density and compact texture, the TiN,

TiC, and TiNC films have high wear resistance.

ü

Thin films covering layers further improve gloss and

protect against corrosion and discoloration.

Comments

Post a Comment